|

Stan Thompson

| |

[ Uranium Fuel ] [ Breeding Pile ] [ Bad Shit ] [ SGT's Facilities ] [ SGT's Process ] [ Michele Gerber ]

Thompson's Facilities

From: PLUTONIUM PRODUCTION STORY AT THE HANFORD SITE:

PROCESSES AND FACILITIES HISTORY (Document Number WHC-MR-0521

)

by Michele Gerber, Ph.D. and is

available to download.

Thumbnail images have been added to Gerber's text by the Webmaster.

Click on the thumbnail for a full sized image.

4.0

RADIOCHEMICAL SEPARATIONS PROCESSING

AT THE HANFORD SITE

4.1

THE BISMUTH-PHOSPHATE PROCESS

4.1.1

Start-up of Radiochemical Processing at HEW

The earliest radiochemical processing operations at the Hanford Engineer

Works using "hot" (irradiated uranium) feed began at the 221-T Cell

Building, also known as T-Plant or T-Canyon, on December 26, 1944.

This event was historic because T-Plant was the first full-size

radiochemical processing plant in the world.

The only previous radiochemical processing of irradiated uranium fuel

elements had been done on an experimental scale at a facility known as the

Clinton Semi-Works (or SMX), located at the Clinton Engineer Works in Oak Ridge,

TN.[lxxxv]

4.1.2

T, B, and U Process Groups

The original separations process used at HEW was the bismuth-phosphate

(BiPO4) process. It was based

on the principle that bismuth phosphate is similar in crystal structure to

plutonium phosphate. The entire

operation was a batch, precipitation process that achieved separation by varying

the valent state of plutonium 239 (Pu-239), and then by repeatedly dissolving

and centrifuging plutonium-bearing solutions.

The steps of the bismuth-phosphate process were carried out first in T‑Plant,

then in the 224-T Bulk Reduction Building, and then in the 231-Z Isolation

Building. A second and third

set of facilities for both the first and second phases of the BiPO4 process also

were built at HEW, but the final steps always took place in the 231-Z Building.

The second set of facilities was known as the B Process Group, and

consisted of the 221-B (B-Plant) and 224‑B Buildings and their

associated support structures. B-Plant

began processing irradiated U at Hanford on April 13, 1945.

The third set of facilities was known as the U Process Group, and

consisted of the 221-I (U-Plant) and 224-U Buildings and their associated

support facilities. The U Process

Group never handled irradiated uranium, but served as a training facility until

another use for the buildings was developed in 1952.[lxxxvi]

4.1.3

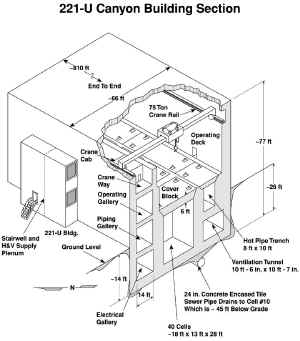

Original Separations Buildings

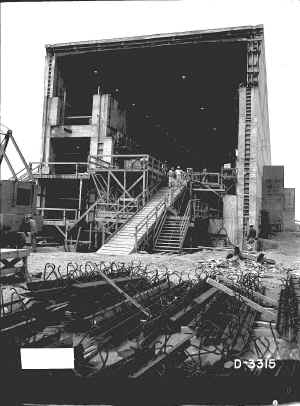

The 221-T Cell Building originally was

85

feet (25.91 meters) wide by 875.5 feet (266.85 meters) long by 102

feet high.

It was a dense, thick, reinforced concrete, rectangular mass,

approximately one-quarter

below grade, with no windows.

At the time that T-Plant was built, its design and construction was

described by the DuPont Corporation builders as "extremely unusual...due to

process requirements. In other

words, once the equipment in any of the cells is placed in operation, it will

not be possible to approach it for maintenance or to manually remove or fit up

piping." Remote

operational requirements, as well as radiation shielding requirements, resulted

in the 221‑T Building being unique, and a first-of-a-kind structure

in the world, when it was built.

The

221‑B Building was virtually identical to T-Plant,

except that it had 65 feet (19.81 meters) less length and did not contain a

special head-end testing laboratory that was included in T‑Plant.

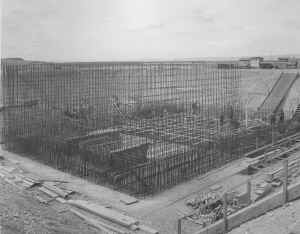

The foundation of each canyon building structure was a reinforced

concrete pad

varying from six

to eight feet (1.83 to 2.44 meters) in thickness

with a spread footing. Outside

building walls were likewise reinforced concrete three

to five feet (0.91 to

1.52 meters) thick.

The barricade wall between the cells and canyon and the galleries was seven

feet

(2.13 meters) thick.

Each

building had a suspended flat concrete roof varying from three

to four feet (0.91

to 1.22 meters) in

thickness.

Construction joints were provided between each building section and

expansion joints at frequent intervals. The

inside surfaces of the cells and pipe trench, removable cover blocks, the deck

floor level in each canyon, and each second floor control gallery were painted

with "Amercoat,"

an epoxy-based contamination fixant sealant, to reduce the porosity of the

concrete surfaces.

Each 221 Building structure was separated into two main portions -

Galleries and Canyon, with the inside of the building being divided into 22

sections (for T-Plant) and 20 sections (for B-Plant).

Each section encompassed two cells.

Sections were 40 feet (12.19 meters) long with the exception of

Sections 1, 2, and 20, which were 44 feet (13.41 meters), 43 feet

(13.11 meters), and 43.5 feet (13.26 meters) respectively.

Inside the head-end of T-Plant, were two developmental equipment cells, A

and B, having the same length as cells 1, 2, 3, and 4 [a total of 65 feet

(19.81 meters) in length]. The

essential difference between this testing laboratory and a standard T-Plant

section was that each testing laboratory cell contained the equipment

corresponding to that in two standard cell sections.

The head-end laboratory section also included a continuation of the

basement, first and second floor galleries that ran the length of T-Plant.

However, these galleries turned at the head-end and continued across to

the rear wall of the building.

4.1.4

Galleries

The HEW canyon buildings were so designed that the control panel boards,

chemical and service distribution, were located in three galleries, one above

the other along the "front" side of the building; the west side in the

case of T-Plant and the north side in the case of B-Plant.

The first gallery, at the basement level, was used principally for

electrical distribution and control cabinets.

The first floor gallery consisted of a piping loft containing steam,

water, air, and chemical headers as well as piping connections between the panel

boards and weigh tanks on the second floor and through-wall cell piping.

The second floor gallery was the control center for the cell equipment,

and was known as the operating gallery. Each

40-foot building section constituted a separate unit, and were controlled by

separate gauge boards in the operating gallery.

The gauge board panels were installed in a row along the barricade wall

between the canyon and the galleries, with weigh tanks along both front and back

walls of the gallery.

4.1.5

Canyon

The lower portion of the canyon below the "deck" (ground) level

contained 40 individual concrete cells having removable concrete cell-block

covers. The cell covers were

constructed with overlapping, step-wise edges, to contain the radiation within

the cells. A 10-foot (3.05‑meter),

6‑inch (15.24‑centimeter) square exhaust duct ran along the back

wall of the building paralleling the bottom of the cells and was connected by an

underground concrete duct to the 291 Exhauster Buildings and Stacks for the

removal of cell fumes. Immediately

above this duct was a pipe trench which also paralleled the cells, containing

inter-connecting cell piping. The

pipe trench was also covered with removable, sectional concrete block covers.

The construction of the cells was standardized as much as possible, to

ease the maintenance problems as much as possible.

The sections having standard designs were 4, and 6 through 20.

Section 1 differed in that it was a large cell with two long openings for

the immediate storage of partially processed material.

Section 2 contained two long openings of the same size, one of which

centered over the railroad track where irradiated fuel elements were brought

into the building, and the other which housed initial cell equipment.

A reinforced concrete railroad tunnel, extending 150 feet from the front

sides of the buildings provided rail service to this section.

Section 3 differed in that the pipe trench ended opposite cell #5.

Section 5 differed in that cell #10 was much deeper, because it served as

a collection point for drainage to the sewer section.

At T-Plant, the head-end sections differed in that the pipe trench

terminated in a manner that would allow for future extension of the building if

desired. (Such extension did not

happen.)

4.1.6

Processing Equipment

The equipment installed in the cells consisted mainly of centrifuges and

vessels with and without agitators, and connecting piping between cell walls and

equipment. Around the periphery of

each cell were 42 flanged piping connections serving the cell equipment.

Special piping connectors were used allowing pipes, conduits, and

instrument leads to be connected by tightening a single nut.

Vertical connectors were used for electrical connections only, and

horizontal connectors were used for piping and instruments only.

The canyon portion of each Cell Buildings was served by an overhead

bridge crane equipped with 75-ton and 10-ton hooks as well as four independent

monorail hoists of one and one/half-ton capacities.

The crane cab was designed to contain special controls, observation and

communication facilities in order to remove cell blocks, cell equipment and cell

piping by remote control. The

canyons also each contained a second overhead bridge crane, 10-ton capacity for

maintenance use only, when the building was completely shut down.

4.1.7

Stair Towers

Four-story reinforced concrete stair towers were constructed along the

front side of each 221‑T Building (eight in T-Plant and seven in

B-Plant) to provide access to the three gallery levels and the crane-cab runway.

These stair towers also housed heating and ventilating equipment and rest

rooms for the galleries. Reinforced

concrete labyrinthed stair towers were built along the rear sides (east side in

the case of T-Plant and south side in the case of B-Plant), to provide access to

the canyon portion of each building at the deck level.

T-Plant had ten such rear stair towers and B-Plant had nine.[lxxxvii]

4.1.8

224 Bulk Reduction Buildings

The 224 Buildings were constructed of reinforced concrete.

Each was a three-story frame structure with concrete and concrete block

exterior and interior walls. The

front of each 224 Building was placed precisely 150 feet from the back of its

corresponding 221 Building, and in line with the front of its process

group's 222 Control Laboratory. Each

224 Building contained a total of 21 rooms not including two stair towers, one

closet, one janitor's closet, and an elevator "penthouse."

The overall dimensions were 60 feet (18.29 meters) 1 inch

(2.54 centimeters) by 197 feet (60.05 meters) long, with a total area

of 11,982 square feet (1 113.16 square meters).

Each building was 40 feet (12.19 meters) high for the majority of

its length, but reached higher elevations over two stair towers and over the

small penthouse area.

The foundation of each 224 Building was comprised of reinforced concrete

walls with spread footings, reinforced concrete piers and beams, and concrete

pads. Each floor slab was

reinforced concrete 4 to 12 inches (10.16 to 30.48 centimeters) thick.

Each roof consisted of flat reinforced concrete 5 to 12 inches (12.70 to

30.48 centimeters) thick, covered with built-up felt, gravel surfaced

roofing, and containing 8 wood frame ventilators with meters.

The roof slabs were removable, so as to allow the movement of large

equipment pieces in and out.

Each 224 Building was essentially divided into two main sections:

the process cell section, and the office and operating gallery section.

The back side of the main structure contained the process cells and had

one foot thick concrete walls with a balcony running around three sides.

The 27-foot (8.23‑meter) by 197-foot (60.05‑meter) process

cell area contained five cells known as Cells A to E inclusive.

These cells were served by a hand-operated overhead crane.

Cells A through D measured 27 feet (8.23 meters) by 28 feet

(8.53 meters). Cell F measured

25 feet (7.92 meters) by 51 feet (15.54 meters), was L‑shaped,

and had an office in one corner of it. A

glass enclosure was located in the cell against this office wall, where the

partially finished product was collected for transfer to the 231-Z Isolation

Building. In Cell C, the right-hand

portion was a pit which connected with an underground pipe tunnel that ran from

the center line of Sections 13 and 14 in the corresponding 221 Building to each

224 Building.

The floors in the cells were sloped to a trench along the wall, for

gravity delivery to waste collection tanks.

The walls and floors in Cells A through E, and walls, floors, and

ceilings in F Cells and its office were painted with Amercoat.

A mezzanine floor extended across the side facing the corresponding 221

Building. Gauge boards and weigh

tanks used in connection with Cell F were mounted on this mezzanine.

One-foot (0.30‑meter) thick interior walls divided the process cell

section of each 224 Buildings from the office and gallery section.

The "front" (offices and gallery) side of the main structure

was reinforced concrete frame with 8-inch (20.32‑centimeter) concrete

block panels and 8-inch (20.32‑centimeter) and 4-inch (10.16‑centimeter)

concrete block partitions. An

elevator was installed adjacent to the No. 1 stair tower and was provided with

an outside concrete loading platform to facilitate the movement of chemicals to

and from trucks. The first floor

contained offices, a chemical storage room, and other service rooms.

The second floor was principally a pipe loft containing five concrete

vestibules opposite each centrifuge platform.

All chemical and service lines entered the building on this level.

The third floor was an operating gallery that contained gauge boards,

tanks, and instruments.[lxxxviii]

4.1.9

231 Isolation Building

The 231-Z Building was located in the western portion of the 200-West

Area of the Hanford Site, midway between T-Plant and U-Plant.

Originally, this structure was a two-story, flat roofed, reinforced

concrete, frame building with 8‑inch concrete block panels and 4‑inch

(10.16‑centimeter) and 8‑inch (20.32 centimeter) concrete block

partitions. Overall dimensions were

147 feet (44.8 meters) by 189 feet (57.61 meters) 10‑inch

(25.40 centimeters) by 24 feet (7.32 meters) 6‑inch

(15.24 centimeters) tall, with a total of 27,964 square feet

(2597.94 square meters). A

one-story ventilation and equipment room ran along the west end of the building.

The 231-Z facility had no windows.

In World War II, the 231-Z Facility contained a total of 57 rooms

including 20 laboratories, several process and chemical receiving and

storage rooms, offices, change room facilities designed to accommodate 190

employees, air conditioning equipment, a distilled water system, ventilation and

exhaust systems, and a compressed air system.

Six of the laboratories were known as "cell laboratories," and

served as the major centers where the actual Pu isolation process was carried

out. All of the rooms except for

one rest room were located on the first floor, with the second floor serving as

a pipe and service loft containing duct work and filters for the ventilation and

exhaust systems.

The interior of the 231-Z Building was configured with two 8 foot

(2.44‑meter) wide, north and south corridors, A and B; one on each side of

the (6) cell laboratories with emergency exits to the outside of the building.

Corridors C and D ran east and west, connecting with corridor B.

Corridors E and F ran north and south separating laboratories and

intersect corridors C and D. Two

concrete stairways led to the second floor, and below-grade piping led to a

waste disposal system. This piping

was modified in 1948 to achieve additional control of 231-Z process wastes.

The 231-Z Building foundations consisted of reinforced concrete piers

with spread footings and concrete walls with spread footings.

Floors were reinforced concrete varying from 4‑inches (10.16‑centimeters)

to 12‑inches (30.48 centimeters) in thickness.

The walls and ceilings of the cell laboratories and Vaults A and B were

reinforced concrete 1 foot thick. The

roof was likewise reinforced concrete 4‑inches thick and was covered with

built-up felt, gravel surface roofing containing numerous openings for intake

and exhaust ducts. The walls,

floors, ceilings, and equipment in rooms 1 to 6, 8, 27, 31 to 45, Vaults A and

B, and corridors A, B, C, D, E, and F were painted with "Amercoat" to

obtain non-porous surfaces.[lxxxix]

[lxxix].

Erickson, UNI-1437, Rev. 2, pp. 5-6, 10, V-1; Scott, UNI-1960, pp. 1-3,

13-17; Newby and Marshall, UNI-2109; Lyon, UNI-2110; Nelson, UNI-3422; Nelson,

UNI‑3329; Zaloudek and Ruff, UNI-3653 (PNL-5924); Zaloudek and Ruff,

UNI-38994 (PNL-5930); Lee, UNI-4193; Nelson, UNI-4191 Rev. 1; Alzheimer and

Gonzalez, UNI‑4285; Martek, UNI-4263; Lyon, UNI-1986; Cummings,

UNI-2063; Rainey, UNI‑2182; Conn, UNI-2227 Rev. 1; DeMaria, UNI-3481 Rev

1; Shoemaker and Fuller, UNI-21016; Reeves, UNI-610 Rev. 1; Lechelt, UNI-2925;

Lattin, UNI-3333; Rasmussen, UNI-3583; Stauch, UNI‑4210; Linschooten,

UNI-4148; Pope, UNI-4239; Smith, UNI-4253; Sullivan, UNI-4225.

[lxxx].

Hanford Engineer Works, HW‑10475‑B, pp. 910-919.

(Note: The exact fuel

storage times used in World War II are not known.

Following the war, storage times lengthened in order to allow for

additional decay (stabilization) of radioisotopes such as Iodine 131.)

[lxxxi].

Foskett, HW-18208; Stark, HW-22824.

[lxxxii].

Watson, Brendel and Shields, WHC0EP-0477.

[lxxxiii].

Harrison, DUN-7711.

[lxxxiv].

Nelson, UNI-2046.

|